In the evolving world of barcode technology, the shift from traditional linear (1D) barcodes to the more robust 2D and 3D barcodes has dramatically enhanced data capacity and operational efficiency across various industries. As these barcode formats have become more complex, so too have the scanners developed to interpret them. Grasping the nuances between 2D and 3D barcode scanners, including "1D vs 2D vs 3D barcode" distinctions, is crucial for businesses focused on streamlining their processes and maintaining a competitive edge in the rapidly changing marketplace.

Overview Of Barcode Scanners

Barcode scanners are pivotal devices for capturing and interpreting the information embedded within various types of barcodes. Traditionally designed to read linear (1D) barcodes, composed of parallel lines of varying widths and gaps, these scanners have evolved significantly. With the advent of intricate "2D vs 3D barcode" technologies, the demand for more advanced barcode scanners has considerably increased, highlighting the transition from simple 1D formats to complex "2D and 3D barcodes."

2D Barcode Scanners

2D barcode scanners are specifically designed to read two-dimensional barcodes, which encode information horizontally and vertically. These "2D barcode vs 3D barcode" systems offer significantly greater data storage capabilities than their 1D counterparts, accommodating alphanumeric characters, symbols, and images. Notable 2D barcode formats include QR codes, Data Matrix codes, and PDF417.

Employing advanced image-based technology, these scanners capture the entire barcode in any orientation and decode the embedded information. Equipped with cameras or imagers, 2D scanners adeptly read barcodes displayed on various digital screens and traditional printed media, underscoring the versatility of "2D barcode scanners" in modern data management systems.

3D Barcode Scanners

3D barcode scanners, often referred to as volumetric or depth scanners, are at the forefront of barcode scanning advancements. Diverging from traditional "2D barcode scanners," these devices are calibrated to analyze three-dimensional objects and surfaces, adding a depth component that transcends flat barcode scanning.

Utilizing sophisticated imaging technologies like structured light or laser triangulation, "3D barcode scanners" efficiently gather detailed spatial data of an object's surface. This capability allows for scanning standard 1D and 2D barcodes and creating precise 3D models, crucial for applications in quality control, reverse engineering, and augmented reality, thus marking a significant leap in "barcode 3D" technology usage.

Key Differences Between 2D And 3D Barcode Scanners

Data Complexity

2D Barcode Scanners: Tailored for decoding information across two dimensions, "2D barcode scanners" significantly surpass traditional linear barcodes in data storage capacity. These devices not only capture basic product identifiers but also details like prices, expiration dates, and URLs, showcasing their advanced utility.

3D Barcode Scanners: In contrast, "3D barcode scanners" focus on acquiring complex spatial data from three-dimensional objects and environments. They provide detailed insights into an object's physical attributes—shape, size, and texture—going beyond mere pattern recognition. This extensive data gathering is pivotal for high-precision demands in quality control, reverse engineering, and virtual reality applications, demonstrating the expansive scope of "3D barcode technology."

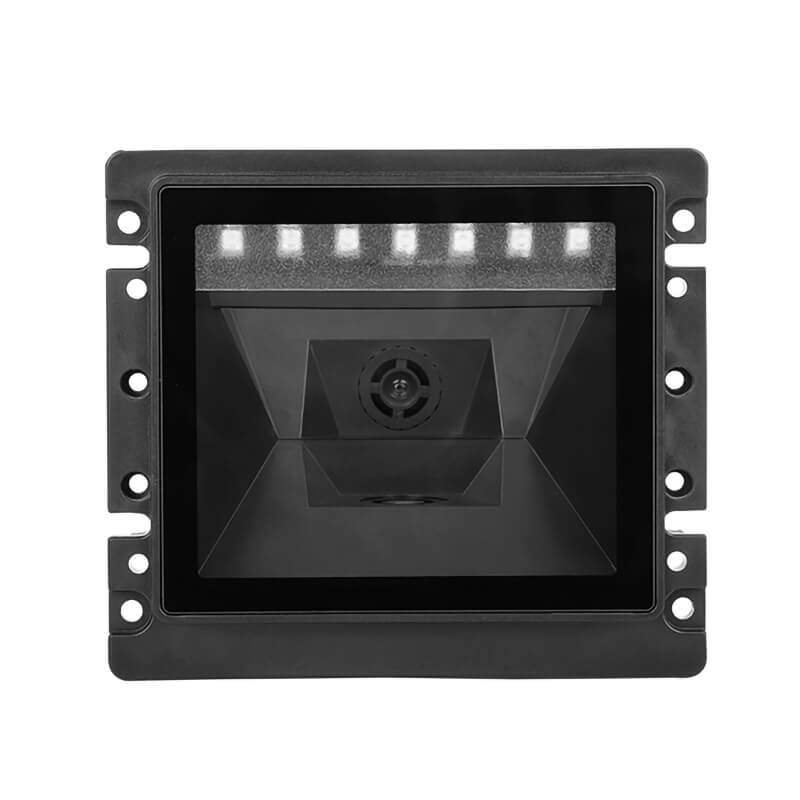

High-Performance Barcode Scanner By Syble

Application Scope

2D Barcode Scanners: The widespread adoption of 2D barcodes has led to their use in diverse industries and applications. In retail environments, 2D barcode scanners are utilized for inventory management, product tracking, and point-of-sale transactions. They also play an important role in logistics and supply chain management, allowing for accurate tracking of products and shipments. Furthermore, 2D barcode scanners are commonly integrated into ticketing systems for events, transportation, and entertainment venues, providing secure and convenient access control solutions.

3D Barcode Scanners: The application scope of 3D barcode scanners is more specialized, focusing on industries where detailed three-dimensional data is essential for decision-making and innovation. In manufacturing, these scanners are used for quality control, ensuring that products meet precise dimensional specifications. By collecting comprehensive anatomical data, 3D scanners let healthcare professionals create bespoke medical devices and implants. 3D scanners are also used in architectural and cultural heritage preservation to document and digitally preserve historical items and structures.

Technology and Functionality

2D Barcode Scanners: The technology behind 2D barcode scanners typically involves image-based scanning. These scanners use cameras or imagers to capture the entire barcode image, regardless of its orientation. This adaptability enables them to scan barcodes shown on displays, such as smartphones or tablets, as well as those printed on a variety of surfaces. Additionally, advancements in 2D barcode scanning technology have led to the development of omnidirectional scanners, which can capture barcodes from any angle, further enhancing efficiency and ease of use.

3D Barcode Scanners: Unlike typical barcode scanners, which collect data from flat surfaces, 3D barcode scanners use sophisticated imaging techniques like structured light or laser triangulation to acquire detailed spatial information. These scanners analyze the physical properties of objects, including their shape, size, and texture, to create accurate three-dimensional models. By utilizing sophisticated algorithms and sensor technologies, 3D barcode scanners offer high precision and resolution, enabling precise measurement and analysis of complex geometries.

Conclusion

In summary, each barcode scanner type presents unique benefits. The choice between "2D and 3D barcode scanners" should align with specific business needs and application requirements. SYBLE is committed to offering a broad spectrum of barcode scanners tailored to diverse industry needs. For more information on how our products can enhance your data management and scanning processes, visit our website and explore our extensive offerings today!