The error tolerance of a barcode scanner refers to its ability to accurately read barcodes that are partially damaged, blurred, contaminated, or distorted. The higher the error tolerance, the better the scanner can adapt to low-quality barcodes. Below are the key factors affecting error tolerance and common technical standards:

1. Key Factors Affecting Error Tolerance

(1) Barcode Type

1D Barcodes (e.g., EAN-13, Code 128):

Error tolerance relies on checksum algorithms and redundancy design (e.g., Code 128 includes a built-in checksum digit).

2D Barcodes (e.g., QR Code, Data Matrix):

High error tolerance is achieved through error correction coding (e.g., Reed-Solomon algorithm), allowing reading even if parts are damaged.

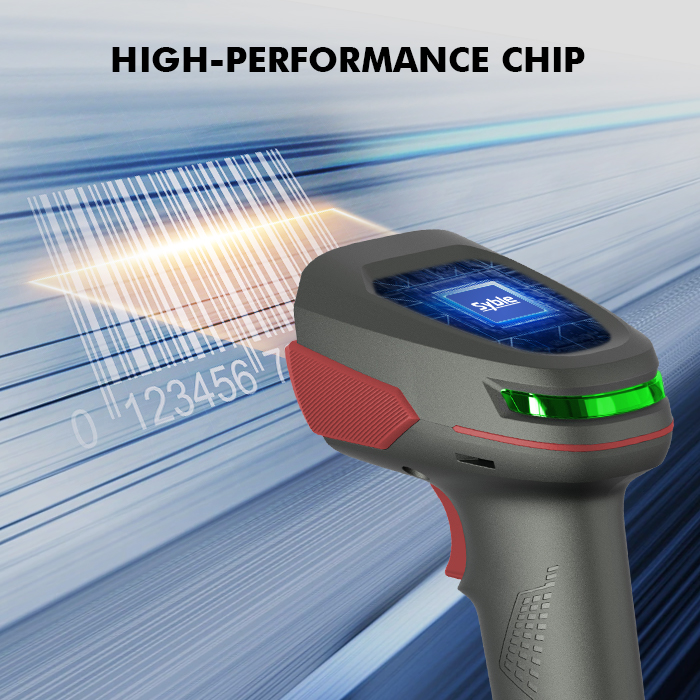

(2) Scanning Technology

Laser Scanners:

Require higher print quality and have lower error tolerance (susceptible to glare and damage).

Imaging Scanners (CCD/Camera-Based):

Use image analysis to recognize blurred or distorted barcodes, offering higher error tolerance.

(3) Barcode Quality

Print Resolution: Low-resolution barcodes are prone to misreads.

Contrast: Insufficient contrast between bars and background reduces error tolerance.

Damage Level: Stains or scratches exceeding error correction capabilities may prevent reading.

2. Technical Standards for Error Tolerance (Example: QR Code)

QR codes have four error correction levels, directly affecting tolerance:

| Error Correction Level | Error Correction Level | Application Scenario |

| L (Low) | ~7% | High-clarity environments (e.g., product packaging) |

| M (Medium) | ~15% | General commercial use (most common) |

| Q (High) | ~25% | Industrial environments (partial contamination) |

| H (Highest) | ~30% | Extreme damage (e.g., logistics labels) |

3. How to Improve Scanning Error Tolerance?

Select barcodes with high error correction levels (e.g., QR Code Level Q or H).

Optimize print quality: Ensure high resolution and strong contrast (black-on-white is ideal).

Use imaging scanners: Better for damaged or curved barcodes (e.g., supermarket checkout).

Control environmental interference: Avoid direct light or reflective surfaces covering barcodes.

4. Real-World Error Tolerance Performance

1D Barcodes: May fail completely if checksum errors or bar distortion occur.

2D Barcodes: Can still be read even with partial obstructions (e.g., damaged QR code corners).

Conclusion

Error tolerance depends on the barcode type, scanning technology, and print quality. For high-tolerance applications (e.g., logistics, warehousing), it is recommended to prioritize 2D barcodes with high error correction levels paired with imaging scanners.