I. Cargo Information Collection

Barcode Scanning

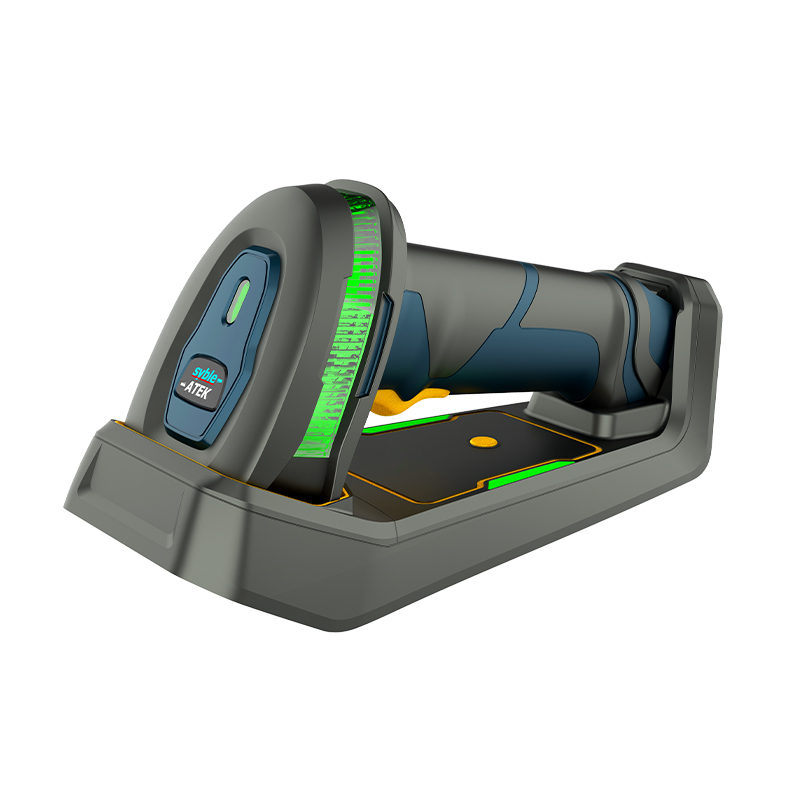

In warehouse management at logistics centers, almost all goods are packaged with barcodes. Scanners can quickly obtain detailed information about the goods by scanning barcodes, such as product name, specifications, production date, shelf life, and place of origin. For example, in e-commerce warehouses, when goods are received, staff use handheld barcode scanners to scan the barcodes on the packaging. This information is then entered into the Warehouse Management System (WMS). This allows for accurate recording of the storage location of the goods, facilitating subsequent searches and management.

In the cargo sorting process, barcode scanners can help sorters quickly identify the delivery destination of the goods. For example, in courier sorting centers, after the scanner reads the barcode on the package, the system automatically directs the sorting equipment to send the package to the corresponding sorting area based on the information in the barcode (such as the recipient's address). This greatly improves sorting efficiency and reduces the errors that may occur in manual sorting.

QR Code Scanning

Compared to barcodes, QR codes can store more information. During the logistics transportation process, the QR code on a transport vehicle can contain information such as the vehicle's license plate number, the company it belongs to, the transportation route, and the estimated arrival time. Logistics managers can scan the vehicle's QR code to get real-time updates on the transportation status. For example, when a vehicle arrives at a logistics hub, staff scan the vehicle's QR code, and the system automatically updates the arrival time and displays the list of goods on the vehicle, facilitating loading and unloading operations.

For high-value or specially managed goods, QR codes can also store traceability information about the goods. For example, in cold chain logistics, the QR code on some fresh agricultural products can record information such as the product's origin, harvesting time, processing procedures, and transportation temperature. By scanning the QR code, consumers and logistics managers can trace the entire circulation process of the product, ensuring its quality and safety.

II. Logistics Equipment Management

Scanning Equipment Identification

In logistics warehouses, there are many types of equipment, such as forklifts and shelves. By attaching unique identification QR codes or barcodes to the equipment, scanners can manage the equipment. For example, warehouse managers regularly use scanners to scan the identification codes on forklifts to record their usage and maintenance records. This facilitates the scheduling of equipment maintenance plans and ensures that the equipment is in good working condition.

For shelves, scanning the identification code on the shelf can provide information about its capacity and the types of goods stored. When goods are received, after the scanner reads the shelf identification code, the system automatically recommends an appropriate storage location based on the shelf's storage status, optimizing the utilization of warehouse space.

Assisting Equipment Troubleshooting

Some advanced scanners can be integrated with the equipment's sensor systems. When a logistics device malfunctions, the scanner can read the fault codes transmitted by the equipment's sensors after scanning the identification code. Maintenance personnel can quickly locate the cause of the fault based on this information, reducing equipment downtime. For example, when an automatic sorting device malfunctions, after the scanner reads the identification code on the device, the system displays the faulty part and the possible cause of the fault, allowing maintenance personnel to perform targeted repairs.

III. Logistics Transportation Monitoring

Tracking the Transportation Process

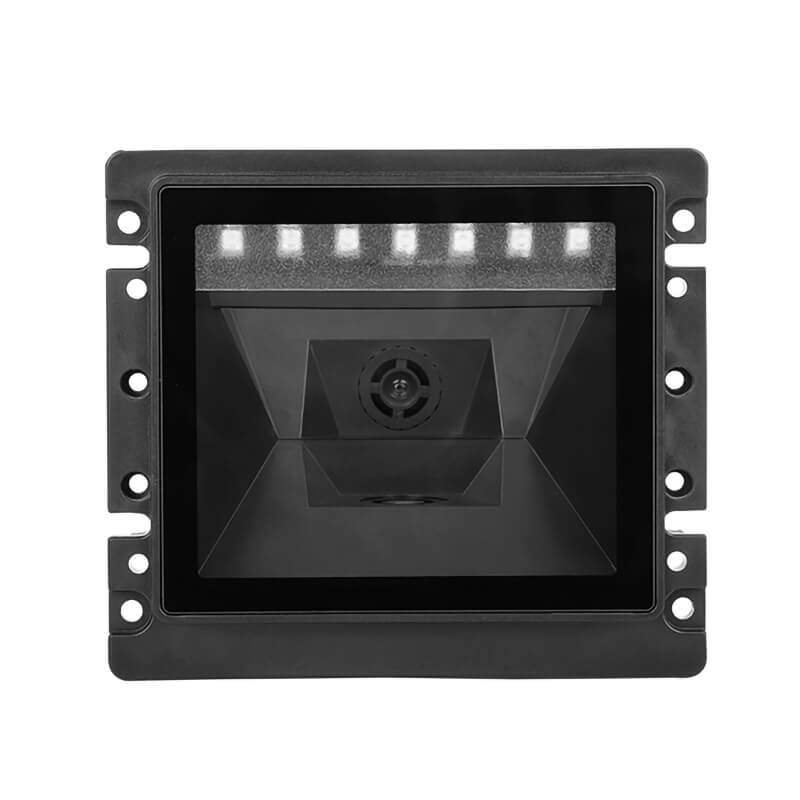

Installing scanning devices with GPS positioning and communication functions on logistics vehicles allows for real-time scanning of transportation status information. For example, scanners can periodically scan information such as the vehicle's speed, route, and cargo status and transmit this information to the logistics monitoring center. Staff at the monitoring center can view the vehicle's real-time location through the monitoring system, ensuring that the vehicle travels along the predetermined route and promptly detecting any anomalies, such as deviations from the route or extended stops.

For maritime logistics, port scanning devices can scan the identification codes on cargo ships to obtain information such as the ship's cargo manifest and estimated arrival time. At the same time, during the loading and unloading of the ship, scanners can read the identification codes on the goods to record the order and time of loading and unloading, improving the efficiency of port operations.

Transport Safety Inspection

During the logistics transportation process, scanners can be used to inspect the safety of goods. For example, in air logistics, airport security scanning devices can scan X-ray images of the goods to check for prohibited items. In rail logistics, scanning devices at railway freight stations can inspect the integrity of the packaging to see if the goods have been damaged during transportation, ensuring that the goods arrive safely at their destination.

Scanners not only improve work efficiency in the logistics field but also enhance the transparency and controllability of the logistics process. They are an indispensable and important tool in modern logistics.